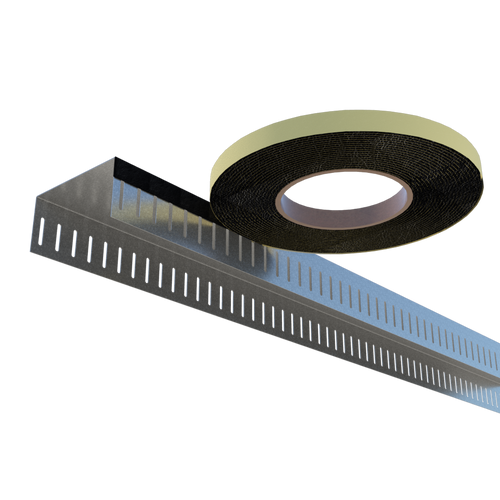

BlazeFrame Tape

A 2mm thickness of cured intumescent material adhered to metal profiles provides air and smoke seals. When exposed to heat above 375 degrees Fahrenheit, the intumescent material expands up to 35 times its size. This provides protection from heat and flame passage during a fire event.

UL 2079-FIFTH EDITION COMPLIANT

When used in conjunction with the applicable BlazeFrame deflection tracks and BlazeFrame Perimeter L-Bead is UL 2079-fifth edition compliant with UL 2079 Class II or III Movement Capabilities.

- Packaged in tape form

- Sold by the case/box-quantity varies by size

- Peel & Stick Adhesive

- Can be field or factory applied

PRODUCT DATA & ORDERING INFORMATION

| Product code | Thickness | Size (in) | Roll Length (ft) | Rolls/Box |

|---|---|---|---|---|

| BFT125 | 2mm | 1-1/4" | 82' | 10 |

- Additional tape widths available, contact Technical Services for details.

TECHNICAL DATA:

UL 2079-FIFTH EDITION COMPLIANT

When used in conjunction with applicable BlazeFrame deflection tracks and BlazeFrame Perimeter L-Bead is UL 2079-fifth edition compliant. Provides joint protection for up to 1" with UL 2079 Class II or III Movement Capabilities.

PRODUCT DATA & ORDERING INFORMATION:

- 2mm thickness

- 3/4", 1" and 1-1/4" widths (additional widths available by request)

- Sold by the case/box-quantity varies by size

- Peel & Stick Adhesive

- Can be field or factory applied

BLAZEFRAME TAPE / BLAZEFRAME DEFLECTION TRACK MATRIX

|

Track Type |

1-1/4" Tape |

|

Slotted Tracks |

DSLW2 = DSLW0 + BFT125 |

|

Deep Leg |

*DLW1 = DLW0 + BFT125 |

|

DLW2 = DLW0 + BFT125 |

|

|

J-Runner |

*JRW1 = JRW0 + BFT125 |

|

Off-Set Deep Leg |

ODLW2 = ODLW0 + BFT125 |

|

Off-Set Slotted |

ODSLW2 = ODSLW0 + BFT125 |

|

Single Leg Slotted |

*SLW1 = SLW0 + BFT125 |

- BlazeFrame Tape to be field installed on one side of track

INSTALLATION:

FIELD APPLICATION OF BLAZEFRAME TAPE:

Preparation:

- Verify that the product to be run is the correct product according to the shop order. This includes verifying web width, leg height, slots, angles, gauge, etc.

- Select appropriate width of tape per system design.

- Before applying any tape, the steel must be wiped down with a dry rag. If any additional oil, grease, prelube, coolants, or other conditions that may prevent the intumescent tape from adhering properly are present, then they must be cleaned off with a degreaser, and the steel must be allowed to dry before proceeding.

Application:

- Position and adhere tape to the proper area following the guidelines:

- Flat top profiles must be taped with a 3/32” offset from the top of the profile. This means that the tape should protrude 3/32” above the web of the product to ensure that the intumescent tape can seal correctly after installation. Allow for + 1/16”, - 0” tolerance.

- Butting tape (when a new roll of tape needs to be started part way through a product), there must not be any gaps between the two pieces of tape. There is zero tolerance for this measurement.

- The tape on each end of the product must overhang by 1/32”. There is zero tolerance for this measurement. This is to ensure that when parts are butted together during installation, the tape from one part touches the end of the tape from the next part.

- On products other than flat top profiles, the tape must be placed according to the shop orders instructions.

- Once the tape is correctly positioned, pressure must be applied evenly along the entire length of the strip to ensure that the tape adheres properly to the steel, a roller device is recommended.

- When applying the intumescent strip to the metal profile, care must be taken to ensure that there are no air pockets and that there are no gaps between abutting pieces of strip. Proper placement of the strip must be maintained and is dependent on the profile shape.

- In conditions which are not conducive to normal tape adhesion (cold temps/high humidity), apply an even coat of 3M High-Strength 90 spray adhesive or similar along the entire area to be taped. Gloves must be worn at all times during the application of the spray adhesive

Recommendations:

- Overlap BlazeFrame Tape gasket per BlazeFrame Constructability designs

- Compatible with non-solvent-based products (caulks, paints, coatings, fire proofing, drywall “mud")

- Provide protection of areas adjacent BlazeFrame Tape using UL classified applications.

- Fasteners driven into BlazeFrame Tape to be driven in complete with gasket sealing around fastener